Fluid Tech Systems, a reputable manufacturer, supplier, and exporter based in Ahmedabad, India, specializes in producing high-quality Crusher Gear Oil Pumps (FTCP). These oil pumps are designed to offer robust and reliable performance in a variety of industrial applications. Built with precision engineering, they ensure smooth operation, long-lasting durability, and efficient lubrication in crusher machinery. Fluid Tech Systems is known for its commitment to innovation and customer satisfaction, offering a range of customized solutions to meet specific client needs. With a strong reputation in the market, they provide prompt and efficient delivery worldwide, making them a trusted partner in the industry.

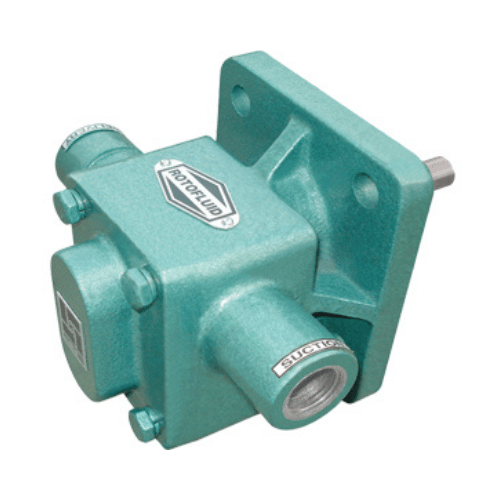

Fluid Tech Systems offers ROTOFLUID brand gear pump Model FTCP which is widely used in crusher gear oil pump. Model FTCP having simple two pieces Cast Iron construction which is spur profile carton steel gears shrunk fitted on alloy steel hardened of grind incised shaft as gear firmly supported 4 nos. of self lubricated sintered bronze bush bearing which ensure smooth running. These pumps can be run in either direction with change in inlet-outlet port position.

Due to the design of Model FTCP Pumps give pressure up to 15 kg/cm and maximum temperature 80C. Suction and delivery available in this model is only 1/2".

| Part | Material For FTCP |

|---|---|

| Body | IS.210 FG 220 C.I. Grade |

| Back Cover | IS.210 FG 220 C.I. Grade |

| Rotor/Stator Shaft | EN-19 |

| Gear | EN-8 |

| Bearing[Bushes] | Non Ferrous Sintered Bronze |

| Sealing | Neoprene oil Seal |

| Key for coupling | EN-8 |