Are you searching for External Gear Pump Manufacturer, Supplier and Exporter from Ahmedabad, India? Fluid Tech Systems is the perfect choice for you. We provide wide range of External Gear Pump (FTX) in affordable prices. We are working as a best oil gear pump manufacturer & supplier from last 35+ Years By the help of with 126+ Skilled Engineers and 1000+ Satisfied Clients Worldwide in 800+ Industries Served. An External Gear Pump is a type of positive displacement pump widely used for fluid transfer and hydraulic applications. It consists of two meshing gears that rotate within a housing. As the gears rotate, they create suction at the pump inlet. The fluid is then transported around the periphery of the gears to the outlet side where it is discharged. This design allows for a smooth and consistent flow of liquid, making external gear pumps ideal for handling fluids such as oils, chemicals, and certain types of fuel.

Model - (FTNXFTBXFTVX)

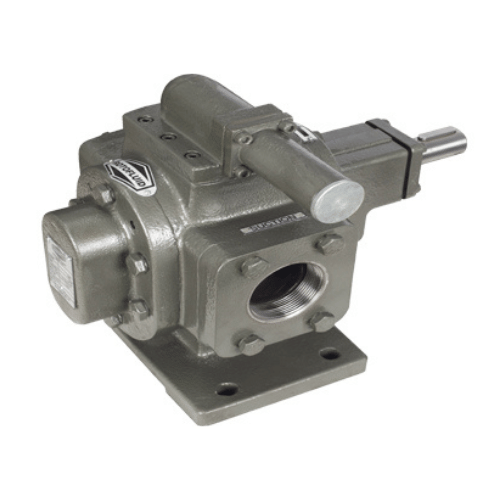

Fluid Tech Systems offer ROTOFLUID brand gear pump Model FTNX/FTBX which is heavy duty flange and foot mounting type external gear pump. Model FTNX/FTB is modified version of Model FTRN/FTRB to achieve high pressure. These pumps having doubled helical finished gears and hardened & ground shafts. Due to double helical gear it prevent axial load and side thrust which help to increase life and performance of pump. Model FTBX is a bush bearing type pump which can be used for viscous liquid having sufficient lubricating value for intermittent duty; however for continuous duty pump have needle roller bearing in Model FTNX and it will be selected for liquid having low viscosity, power lubricating values.

In these pumps size "1" to "2 " are provided with thread at end of suction & delivery and they are available with foot or flange mounting, But in size 3" to 4" are provided with flange at the end of suction & delivery and they are available with foot mounting only. These pumps can be operated up to pressure of 20 kg/cm with 5.0 LPM to 900 LPM flow capacity. These pumps are suitable for liquid up to viscosity of 1, 00,000 SSU and maximum temperature up to 200c.

| Part | Material For FTNX | Material For FTBX |

|---|---|---|

| Pump Body | CI/CS | CI/CS |

| Front Cover | CI/CS | CI/CS |

| Back Cover | CI/CS | CI/CS |

| Gland Cover | CI/CS | CI/CS |

| Rotor/Stator Shaft | EN-19 | EN-19 |

| Gear | EN-24/EN-353 | EN-24/EN-353 |

| Needle/Bush Bearing | INA/IKO [Japan] | Non- Ferrous |

| Wear Plate | Non- Ferrous | Non- Ferrous |

| Sealing | "GFO" Pack Teflon / Mech. Seals | "GFO" Pack Teflon / Mech. Seal |

| R.V. Housing | Mild Steel | Mild Steel |

| R.V. Piston | EN-8 | EN-8 |

| R.V. Spring | Spring Steel | Spring Steel |

| R.V. AD. Screw | EN-8 | EN-8 |

| Key | EN-8 | EN-8s |

| Hex - Bolt | Mild Steel | Mild Steel |

| Model FTNX/FTBX | Suction & Delivery Size | Capacity at 1440 RPM | ||

|---|---|---|---|---|

| LPM | US GPM | M/hr | ||

| 050-S | "" x "" | 05.00 | 1.32 | 0.30 |

| 050-M | "" x "" | 8.33 | 2.21 | 0.5 |

| 050-L | "" x "" | 16.00 | 04.42 | 1.00 |

| 100-S | 1" x 1" | 25.00 | 06.60 | 1.50 |

| 100-M | 1" x 1" | 33.32 | 08.80 | 2.00 |

| 100-L | 1" x 1" | 41.65 | 11.00 | 2.50 |

| 125-S | "1" x "1" | 50.00 | 13.25 | 3.00 |

| 125-M | "1" x "1" | 60.00 | 16.66 | 3.60 |

| 125-L | "1" x "1" | 83.00 | 22.00 | 5.00 |

| 150-S | "1" x "1" | 100.00 | 26.50 | 6.00 |

| 150-M | "1" x "1" | 125.00 | 33.00 | 7.50 |

| 150-L | "1" x "1" | 150.00 | 39.75 | 9.00 |

| 200-S | "2" x "2" | 166.60 | 44.16 | 10.00 |

| 200-M | "2" x "2" | 200.00 | 53.00 | 12.00 |

| 200-L | "2" x "2" | 250.00 | 66.25 | 15.00 |

| 250-S | "2" x "2" | 300.00 | 79.50 | 18.00 |

| 250-M | "2" x "2" | 333.00 | 83.33 | 20.00 |

| 250-L | "2" x "2" | 350.00 | 92.75 | 21.00 |

| 300-S | 3" x 3" | 400.00 | 106.00 | 24.00 |

| 300-M | 3" x 3" | 450.00 | 119.00 | 27.00 |

| 300-L | 3" x 3" | 600.00 | 159.00 | 36.00 |

| 400-S | 4" x 4" | 700.00 | 185.50 | 42.00 |

| 400-M | 4" x 4" | 800.00 | 212.00 | 48.00 |

| 400-L | 4" x 4" | 900.00 | 238.50 | 54.00 |